Other Custom Projects Examples

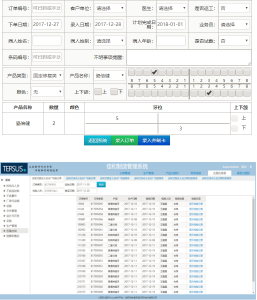

ERP (Warehouse, Quality, Process Tracking, Customer, Finance, Production-barcode scan)

(For dental products)

Specific Requirements:

- Dental Position Select: 32 positions to select, which is show where the product used, refer to left picture

- Multiple Products for each customer: Add or remove products and each product has its type, requirements, position, quantity

- Automatic Notification: Each process has its deadline time and if missed, will notify by email or message

Details:

- ERP + Work Order Management: ERP create work order, tracking work flow and products or status by scan work order

- Reports: More than 50 reports created by system automatically (PDF file download in 5 seconds)

- Print Product Card: Print card for each final product

- Chart: Chart for rework data, quantity finished and open charts, customer order chart

Develop:

- Short Time: Each function module ban be finished in 2 days

- Cloud Server: Developed on cloud server, when finished user can check result as well

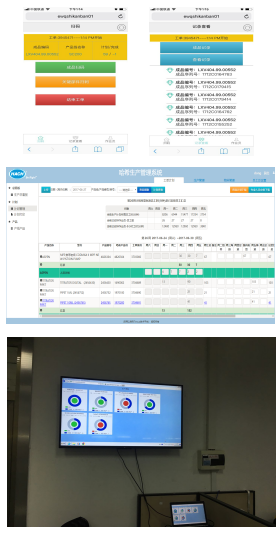

MES (Manufacturing Execution System: Barcode Scan Tracking Process and collect data, Kanban shows error and progress, productivity management)

(A customer from U.S Danaher Group)

Specific Requirements:

- Simple Action on PDA: Just scan and button click, no input on PDA

- Automatically Generate Data: By click button, there will be lots of work done automatically: calculate time cost for each process, calculate on site material quantity, notify warehouse if there is a onsite material shortage, finished good quantity check with target verify process status, notify managers if process data abnormal

- Improve Productivity: By tracking production data, automatically notify other related resources to make sure the progress is ok, collect data to improve process and improve productivity

Details:

- Work order Shipment Plan Arrange on line: Work order, quantity, operators upload, add, change online and print work order which have barcode for scan to collect progress data

- On time Control: On time tracking material, parts, finished goods, operators, progress data

- On Site Management: Calculate production speed to verify process status, if missed target will notify managers automatically

- Automatic Process: By scan to report FG result, automatically check on site material quantity, check engineer resource, notify warehouse, production speed and status, key parts tracking, time and operator tracking

- Management Support: Progress, production line, status data show on visual board and report, which are refreshed as an interval preset

Develop:

- Short Develop Time: Framework and main pages finished in 1 week, after 2 weeks customer test 1st run, all have been done by 1 developer in 4 weeks

- Mobile Function (PDA): Scan barcode and submit result (click “OK” button), simple actions on mobile devices, tracking work order, key parts, operators

- Server-Side Upgrade: Any request of change or update can be done very quickly on server, no conflicts for other users

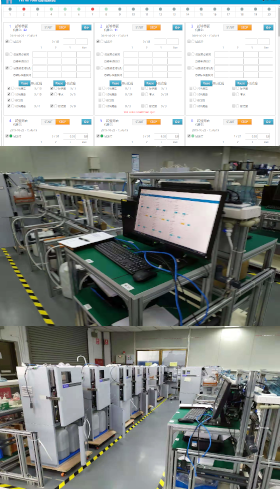

IoT Project (Equipment Monitoring and Control)

(Customer is a Japan company)

Features:

- Equipment Monitoring: Equipment data is collected with RS232 and Modbus protocol, with those data we can monitor equipment progress and current status or anything can be collected

- Ability: 1 pc can connect up to 100 or more equipment, every 100 milliseconds, system will show new data

- Set Control Parameters: By setup parameters we can control the equipment, run or stop, which process and process parameters

- Main Status: Tere is a main status view to show all equipment status, gray, green or red for different status

- Error Message: Any message of equipment status will show on front side

Develop:

- Short Time: 1 month

- Service: Use remote connection tool to update

IoT other solution:

- PLC: If the target has PLC, we can connect to PLC by network or cables, with the support of PLC control data point and code, we can request data from PLC, save into database for calculation and used on Kanban Board or Report

- Add Data Collection Devices: If no control system on equipment or facilities, we may have to add some devices to collect data, for example, we can add a counter device and collect quantity from production lines, and use a network device to send data periodically to database

- Equipment Cloud Data Center: More and more equipment are upgraded which have the data collection function, data will be collected equipment to use or send to a cloud data center, we can check with manufacturers ask for those data

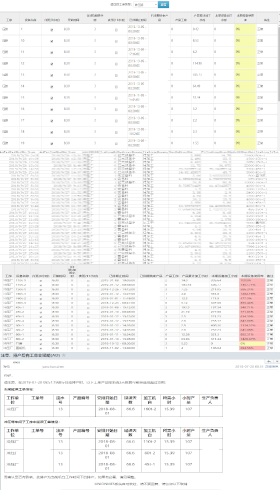

APS (Advanced Planning Scheduling, Work Order / Task Planning, can be used together with ERP or MES system; tested with 4 factories 800 work orders, more than 100 equipment, with multiple processes in 1 work order, all can be planned in 28 seconds)

(A customer from Germany)

Features:

- Auto Planning: Preset stop date, productivity of each equipment or line, priority of equipment, line speed, prepare time, product data, process data, extra time used we can run the function to get work orders arranged on specific equipment and get start datetime and finish datetime, we can set it as an automatically job run at night

- Combine Work Orders: If same products can combine together, save time of preparation for tools and equipment and other setting jobs

- Quantity Limit: If over the limit of tool or equipment, will stop and arrange on other tool or equipment

- Insert Order Manually Insert work order or set a datetime or run all work orders with inserted new together to get new plan

- Sub Process: Each work order may have multiple process and work order have to arrange to each process as well

- Work Loading of Equipment/Line: Work Order progress report, on time complete rate, delay rate, loading rate, used or waiting for orders, result notification (not planned orders, overdue orders), stop date check and notification

Develop:

No Script: Use Visual Programing and no any code in this project

Short Time: 3 week finished main functions by 1 developer, update and test run 4 weeks, totally finished in 7 weeks

Plan Result: Get the result time identified to seconds, next start time same as last finished datetime

Low Cost: Cost time is 7 weeks and cost less than other APS system

Kanban System – Material Tracking Board

(Customer is U.S Molecular Devices Inc)

Features:

- e-cards: Use e-cards, scan card barcode to set the status of material card, issue card, update related information, close card by upload a list of cards part number, all progress data saved automatically for tracking

- Share Data on line everywhere: All departments such as production, buyer, warehouse, logistics, supplier can get same information by check on line or get excel file send automatically by email

- Support Management: Managers get overdue list report every day, no progress update list report, buyers get list of their own and don’t need check others

- Management Reports: Reports can be set to send automatically each day or each hour or specific time, reports content is based on owner

- Automatic Notification: All kinds of notification such as new card, finished card, overdue card, close card list or other information can be sent automatically by email

Main Functions:

- Simple: PDA scan to issue e-card, no other actions required; buyer and warehouse check on line, don’t need to find production card and saved time

- E-Kanban on TV: 1 system, can be used in multiple plant and for each production line shows its own data on line TV; data on TV refreshed every 1 minute, ecard data show on TV with different colors

- Report or list: all kinds of report or list designed according to customer’s request, and mostly send to each owner automatically by email

- Upload List to close: Warehouse pickup material by download open card list, which shows what part, where used, and quantity, when material prepared from warehouse and ready on production line, the card will be updated as close by upload a list of card part numbers, saved time, don’t need collect or update one by one

Develop:

- Short Time Used: Framework and main functions finished in 1 week, customer test run in 2 weeks, totally 3 weeks

- Mobile: Use PDA devices to issue card and close card

- Test on Cloud Server: Quickly for upgrade and test use

- Deploy on Internal Server: User remote connection tools to update according to any new request